Photo by Tekton

Photo by TektonOriginally Posted On: https://www.mudgefasteners.com/fastener-help-articles/determining-torque

The function of a bolt is to apply sufficient clamp force such that when external forces are applied no separation or transverse movement will occur.

Tightening fasteners to apply that clamp force using calibrated torque tools is certainly preferable to simply going by feel. Or, as one senior technician calls it “The One Grunt or Two Grunts Method”. However measuring torque alone does not ensure a proper installation.

Torque is an indirect indicator of Tension.

It is the measure of the twisting force that threads fasteners together.

Tension is the force that holds an assembly together. Think of it this way:

A bolt will stretch, like a spring, as it is tightened once all the parts of the assembly are brought together.

The more torque that is applied to the fastener the more tension is created as the bolt stretches.

If a bolt is like a spring and more torque equals more tension, why doesn’t a certain amount of torque always result in the same amount of tension?

While the relationship between torque and tension is linear, many factors can affect this relationship including surface texture, human error, rust, oil, debris, even material type and locking elements. For this reason the results of tightening to a specific torque setting can vary in the field or on the assembly line.

There is a method used to estimate the torque/tension relationship in an assembly. The Torque/Tension Equation; T = (K D P)/12 can be used to prescribe a torque value that will achieve a certain tension or clamp load.

T = Torque (ft.-lbs.)

D = Nominal Diameter (inches)

P = Desired Clamp Load Tension (lbs.)

K = Co-Efficient of Friction

The K factor can vary depending on the condition of the threaded fasteners.

Commonly used factors range

0.10 = Lubricated with wax, oil or other coating

0.20 = Plain, uncoated

0.30 = Galvanized

0.30+ = Dirty or Rusty

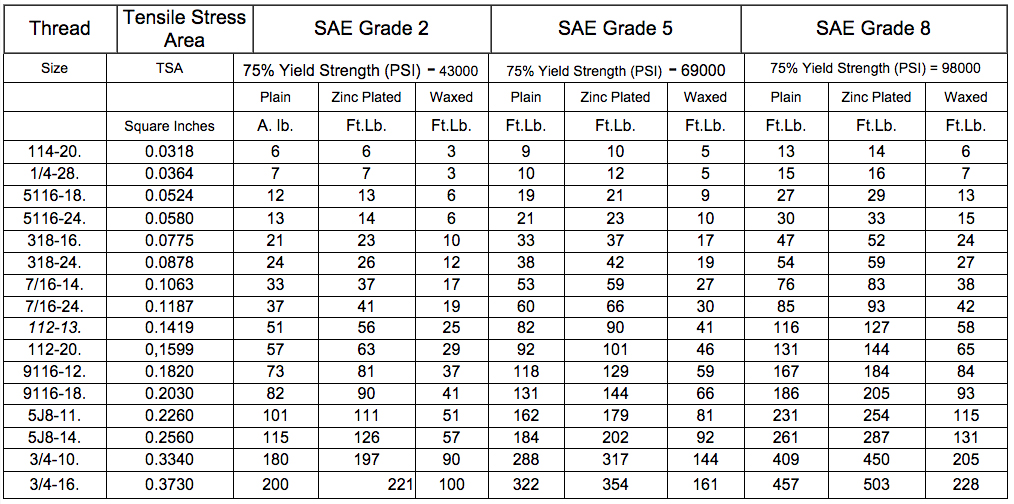

Most Bolt Torque Charts use this formula. Because these are estimates and conditions can vary in real world applications this formula and torque charts should only be used as a guide.

“The best way to determine correct torque is through experimentation under actual assembly conditions.

“

Other methods of achieving specific Clamp Load are:

Turn-of-the-Nut. Specific Tension can be accurately correlated to the amount of rotation of a fastener once the parts of an assembly have been brought together.

Direct Tension Indicator. Used in some structural applications, a DTI washer has protrusions that compress as the joint is tightened. The amount of that compression is measured by a feeler gage that correlates to a specific tension. Another type of DTI washer is the Squirter® type that contains a small amount of silicone material that is expelled when the proper tension is reached.

Need more info than you see here about torque? Call us at (800) 634-0406.