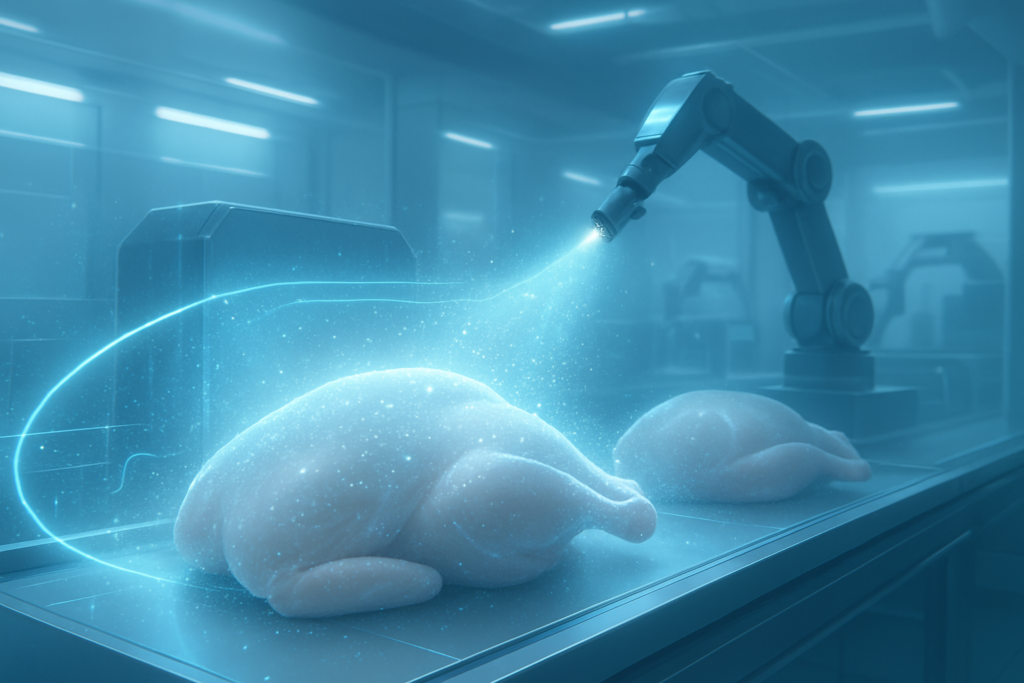

In a significant leap forward for food processing innovation, electrostatic spray technology is rapidly transforming pathogen reduction strategies within the poultry industry. This advanced application method promises not only a dramatic enhancement in bacterial kill rates but also substantial reductions in chemical consumption and water usage, heralding a new era of efficiency and sustainability for poultry processors worldwide. As the industry grapples with ever-increasing demands for food safety and operational cost-effectiveness, this technology emerges as a critical tool, poised to redefine standards for microbial control.

The immediate significance of electrostatic spraying lies in its ability to deliver antimicrobial agents with unparalleled precision and coverage. Unlike traditional methods that often struggle with overspray and inconsistent application, electrostatic systems ensure that disinfectants reach every contour of poultry products, including microscopic crevices where dangerous pathogens frequently reside. This targeted approach translates directly into safer products for consumers, reduced environmental impact through conservation of resources, and considerable economic benefits for processing facilities.

Precision Warfare: The Technical Edge of Electrostatic Pathogen Control

At its core, electrostatic spray technology leverages the fundamental principle of "opposites attract" to achieve superior antimicrobial application. The process begins with the atomization of antimicrobial solutions, typically peracetic acid (PAA) or hypochlorous acid, into incredibly fine droplets, often as small as 30 to 40 microns – a stark contrast to the roughly 300-micron droplets produced by conventional sprays. As these minuscule droplets exit the nozzle, they are imbued with an electrical charge, usually negative. Poultry carcasses and processing equipment, naturally possessing a positive or grounded charge, then act as powerful magnets, drawing the charged droplets towards them.

This electrostatic attraction results in a unique "wrap-around" effect, where the antimicrobial agent adheres uniformly to all surfaces of the product, even those not directly in the spray path, such as the underside of a chicken or within feather follicles. This comprehensive 360-degree coverage is a game-changer for pathogen reduction. Studies have consistently demonstrated impressive bacterial kill rates, with in-plant pathogen log reductions ranging from 2.0 to 2.6 or better when using PAA, significantly surpassing the 1.0 to 1.75 log reductions typically achieved with conventional methods. For instance, one U.S. poultry facility reported a 1.2 log reduction post-treatment on poultry parts, showcasing the technology's efficacy against prevalent threats like Salmonella, Listeria, E. coli, and Campylobacter.

The technical prowess of electrostatic spraying dramatically differentiates it from previous approaches, such as immersion dip tanks and traditional in-line spray systems. Dip tanks, while offering high coverage, are notoriously resource-intensive, requiring vast volumes of water and chemicals that quickly become contaminated, leading to frequent replenishment and disposal challenges. Traditional spray systems, while more resource-efficient than dips, suffer from significant overspray and an inability to achieve uniform, all-encompassing coverage, resulting in wasted chemicals and reduced efficacy. Electrostatic technology, by contrast, boasts a significantly higher transfer efficiency – researchers have observed a 7-fold increase in spray deposition and a 1.6 to 24-fold increase in deposition over conventional methods – translating directly into a monumental reduction in chemical consumption, often by 50% to 95%, and water usage, potentially by as much as 95%. This precision not only enhances food safety but also drastically cuts operational costs and improves worker safety by reducing airborne chemical mist.

Initial reactions from the AI research community and industry experts, particularly those focused on automation and efficiency in food processing, have been overwhelmingly positive. The technology is viewed as a critical advancement that aligns with the broader trend of leveraging intelligent systems for optimized industrial operations. Its ability to deliver measurable improvements in food safety metrics while simultaneously addressing sustainability concerns positions it as a leading innovation in the sector.

Corporate Impact: Reshaping the Food Processing Landscape

The advent and increasing adoption of electrostatic spray technology are creating significant competitive shifts within the food processing industry, particularly for companies focused on poultry. Innovators and early adopters of this technology stand to gain substantial strategic advantages, potentially disrupting traditional market dynamics. Companies like Electrostatic Spraying Systems Inc. (ESS) (ESS: NASDAQ), based in Watkinsville, Georgia, are at the forefront, leveraging over 30 years of experience and patented technologies, including licensed NASA electrostatic technology for advanced nozzles. ESS's owner and chairman, Bruce Whiting, is a frequent advocate, highlighting its transformative potential.

Other major players are also making significant strides. Diversey (DSEY: NASDAQ), through its Birko brand, has developed the "Elite 360®" system in partnership with Colorado State University, an enclosed electrostatic chamber designed for 100% product coverage without overspray. Spraying Systems Co. is another key provider, offering a range of precise spray technologies for the meat and poultry industry. Furthermore, companies like OTSON are specializing in liquid electrostatic spray coating technologies for the broader food and beverage industry, emphasizing increased coating savings and improved transfer efficiency for various applications, including sanitizers. These companies are poised to benefit immensely from the growing demand for more efficient and effective pathogen control solutions.

The competitive implications for major food processing equipment suppliers and chemical providers are profound. Traditional spray nozzle manufacturers and suppliers of bulk antimicrobials may face pressure to adapt or partner with electrostatic technology providers. Companies that can integrate these advanced systems into their offerings will gain a significant market positioning advantage, attracting processors eager to reduce operational costs, enhance food safety, and meet stringent regulatory and consumer demands for sustainability. This technology has the potential to disrupt existing products and services that rely on less efficient application methods, pushing the industry towards higher standards of precision and resource conservation.

Wider Significance: A Paradigm Shift for Food Safety and Sustainability

Electrostatic spray technology in poultry processing represents more than just an incremental improvement; it signifies a paradigm shift in food safety and sustainability practices. This innovation fits seamlessly into the broader AI and automation landscape by demonstrating how targeted, intelligent application can optimize industrial processes, reduce waste, and enhance product quality. While not a direct AI application, its precision and efficiency embody the principles of smart manufacturing that AI often facilitates, pushing the boundaries of what's achievable in automated food production environments.

The impacts are far-reaching. From a public health perspective, the enhanced bacterial kill rates mean safer poultry products, reducing the incidence of foodborne illnesses associated with pathogens like Salmonella and Campylobacter. Environmentally, the drastic reduction in water and chemical usage aligns perfectly with global sustainability trends and corporate responsibility goals, offering a tangible solution to resource scarcity and waste management challenges. For processors, it translates into significant operational savings, improved compliance with increasingly strict regulations, and a stronger brand reputation built on superior food safety standards. The technology also makes the use of newer, more expensive, but ecologically friendly antimicrobials like bacteriophages economically viable, further expanding the arsenal against pathogens.

While the benefits are substantial, potential concerns include the initial capital investment required for adopting these advanced systems and ensuring seamless integration into existing processing lines. However, the long-term return on investment through cost savings and enhanced safety is expected to outweigh these initial hurdles. This development stands as a significant milestone, comparable to previous breakthroughs in food preservation or processing automation, by offering a scalable, effective, and sustainable solution to a critical industry challenge.

Future Developments: The Road Ahead for Precision Pathogen Control

Looking ahead, the trajectory for electrostatic spray technology in poultry processing is one of continued innovation and broader integration. Near-term developments are likely to focus on optimizing system designs for various poultry product types and processing line configurations, ensuring maximum adaptability and efficiency. We can expect further research into the compatibility of electrostatic systems with an even wider array of antimicrobial agents, including novel biological solutions, to tackle emerging pathogen strains and resistance. Automation will play an increasingly crucial role, with electrostatic sprayers becoming integral components of fully automated processing lines, potentially leveraging AI-driven sensors and robotics for real-time pathogen detection and ultra-precise, adaptive application.

Potential applications and use cases on the horizon extend beyond primary pathogen reduction. The technology could be adapted for applying protective coatings, enhancing shelf life, or even delivering flavor enhancements with minimal waste. Experts predict a future where electrostatic technology is not just a standalone intervention but a deeply integrated part of a holistic, data-driven food safety management system. Challenges that need to be addressed include reducing the cost of entry for smaller processors, developing standardized protocols for efficacy validation across diverse plant environments, and training the workforce on operating and maintaining these advanced systems.

What experts predict will happen next is a rapid acceleration in adoption rates as the economic and safety benefits become undeniable. The technology's capacity for resource conservation will become a key driver, especially in regions facing water scarcity or stringent environmental regulations. We can anticipate further consolidation and partnerships within the industry, as technology providers and food processors collaborate to develop bespoke solutions and push the boundaries of what's possible in pathogen control.

Wrap-Up: A New Era of Safety and Efficiency

In summary, electrostatic spray technology marks a pivotal advancement in poultry processing, offering a robust solution to the persistent challenge of pathogen control. Its core advantages—superior bacterial kill rates through comprehensive "wrap-around" coverage, drastic reductions in chemical consumption (50-95%), and significant water savings (up to 95%)—collectively represent a monumental leap forward in operational efficiency and food safety. This technology is not merely an improvement; it's a fundamental shift towards more precise, sustainable, and economically viable pathogen intervention strategies.

This development's significance in the history of food processing innovation cannot be overstated. It moves the industry beyond resource-intensive, often inefficient, traditional methods, ushering in an era of targeted application that benefits public health, environmental sustainability, and corporate bottom lines. The strategic advantages it offers to companies like Electrostatic Spraying Systems Inc. (ESS: NASDAQ) and Diversey (DSEY: NASDAQ) are clear, positioning them as leaders in a rapidly evolving market.

In the coming weeks and months, the industry will be watching closely for further adoption trends, new product integrations, and the continued validation of long-term benefits. This technology is a testament to the ongoing pursuit of excellence in food production, demonstrating how intelligent application can deliver safer food with a smaller environmental footprint.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.