HALIFAX, NS / ACCESS Newswire / January 22, 2025 / Namibia Critical Metals Inc. ("Namibia Critical Metals" or the "Company" or "NCMI") (TSXV:NMI)(OTCQB:NMREF) is pleased to announce key results of the hydrometallurgical scale-up and mini pilot plant test work leading to the production of a high purity rare earth element (REE) carbonate product for its "Lofdal 2B-4" heavy rare earth (HREE) project.

Pilot-scale test work at SGS Lakefield resulted in a simplified flow sheet. The removal of crude REE precipitation, re-leach and thorium solvent extraction forms a significant simplification and is leading to reduced overall reagent consumption.

The Company also announces that its joint venture partner, JOGMEC, has approved an additional $550,000 CDN budget for JOGMEC's fiscal year ended March 31, 2025. This brings JOGMEC's total expenditure commitments to $15,091,000.

Darrin Campbell, President of Namibia Critical Metals, stated:

"We are very pleased to have successfully completed the pilot-scale hydrometallurgical test work for our PFS "Lofdal 2B-4". SGS again demonstrated their ability to innovatively modify the flow sheet resulting in further simplification and reduced reagent consumption. The detailed results will now be evaluated by our engineering and financial team and will form the basis of the PFS report expected later this year as we work to mitigate increased inflationary costs from our November 2022 PEA."

Hydrometallurgical Test Work

Tests were conducted using a 93 kg pilot plant flotation concentrate sample with an average grade of 2.65% TREO produced at SGS Lakefield, using run-of-mine material from the Lofdal Area 4 starter pit.

Bench scale hydrometallurgical tests were conducted showing recoveries of around 94% terbium (Tb) and dysprosium (Dy) using a two-stage acid bake process at 300°C and 650°C.

The SGS pilot rotary kiln was used to scale up from static acid baking to continuous testing in short 6-8 h commissioning campaigns and a longer 72-84 h pilot campaign.

The calcines produced in the acid bake campaigns were combined and water leached batch-wise. The pregnant leach solution (PLS) was subsequently used in a series of bench scale and continuous liquor treatment tests.

Test Results

The original flowsheet consisted of Impurity Removal (IR), Crude Rare Earth Carbonate Precipitation (RP), Re-Leaching (RL) of the crude carbonate precipitate to produce a concentrated REE liquor followed by Uranium IX and Thorium SX, and final REE recovery as calcined oxalate or carbonate.

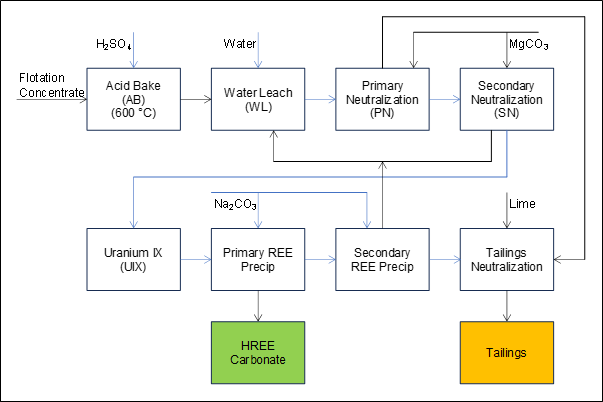

Current test work has shown that a significantly simplified flowsheet consisting of two stage (primary and secondary) impurity removal/neutralization, followed by Uranium IX and two stages (primary and secondary) of REE carbonate precipitation is able to produce high grade HREE carbonate.

Under optimum operating conditions, continuous high temperature (600°C) sulphation in the SGS rotary kiln yielded high HREE dissolution (90-94% Tb and Dy). A composite water leach liquor was produced containing around 1.6 g/L REE and co-extracted impurities such as thorium, uranium, scandium, iron and aluminium.

Batch testwork was used to show that two stages of impurity removal using magnesium carbonate was able to remove practically all (below analytical detection limits) thorium, scandium, iron, aluminium, and some of the uranium at minimum losses of HREE (~ 2%). Uranium was removed by ion exchange (UIX) using a conventional strong base anion resin with negligible co-extraction of HREE.

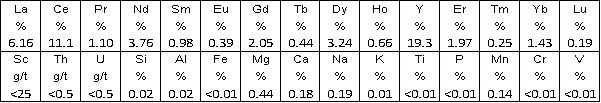

The UIX barren liquor was used in a mini pilot plant where REE-carbonate was recovered in two stages (primary and secondary) of precipitation using sodium carbonate. Overall recovery of REE was almost quantitative and around 0.5 kg of REE carbonate precipitate was produced containing 3.24% dysprosium, 0.44% terbium and 19.3% yttrium. Thorium impurities of the product are <0.5 g/t Th. A detailed composition is shown below.

Standalone re-leach tests confirmed that any HREE co-precipitated in the Secondary Neutralization (SN) stage and Secondary Rare Earth Precipitation were easily recovered (>99.7%) using excess acidity contained in the Water Leach (WL) PLS. No additional acid is required.

The removal of the original Crude REE Precipitation, Re-Leach (RL) and Thorium Solvent Extraction (ThSX) unit operations forms a significant simplification and is leading to reduced overall reagent consumption. The simplified block flow diagram of the revised flowsheet is shown below.

About Namibia Critical Metals Inc.

NCMI is developing the Tier-1 Heavy Rare Earth Project, Lofdal, a globally significant deposit of the heavy rare earth metals dysprosium and terbium. Demand for these critical metals used in permanent magnets for electric vehicles, wind turbines and other electronics is driven by innovations linked to energy and technology transformations. The geopolitical risks associated with sourcing many of these metals has become a repeated concern for manufacturers and end users. Namibia is a proven and stable mining jurisdiction. The Lofdal Project is fully permitted with a 25-year Mining License and is under a Joint Venture agreement with Japan Organization for Metals and Energy Security (JOGMEC).

About Japan Organization for Metals and Energy Security (JOGMEC) and the JV

JOGMEC is a Japanese government independent administrative agency which seeks to secure stable resource supplies for Japan. JOGMEC has a strong reputation as a long term, strategic partner in mineral projects globally. JOGMEC facilitates opportunities with Japanese private companies to secure supplies of natural resources for the benefit of the country's economic development.

Rare earth elements are of critical importance to Japanese industrial interests and JOGMEC has extensive experience with all aspects of the sector. JOGMEC provided Lynas with USD$250,000,000 in loans and equity in 2011 to ensure supplies of the Light Rare Earths metals suite to the Japanese industry.

Namibia Critical Metals owns a 95% interest in the Lofdal project with the remaining 5% held for the benefit of historically disadvantaged Namibians. The terms of the JOGMEC joint venture agreement with the Company stipulate that JOGMEC provides C$3,000,000 in Term 1 and C$7,000,000 in Term 2 to earn a 40% interest in the Lofdal project. Term 3 calls for a further C$10,000,000 of expenditures to earn an additional 10% interest. JOGMEC can also purchase another 1% for C$5,000,000 and has first right of refusal to fully fund the project through to commercial production and to purchase all production at market prices. The collective interests of NCMI and historically disadvantaged Namibians cannot be diluted below a 26% carried working interest upon payment of C$5,000,000 to JOGMEC for the dilution protection. NMI may elect to participate up to a maximum of 44% by funding pro rata after the earn in period is completed.

To date, JOGMEC has completed Term 2 and earned a 40% interest by reaching the C$10 million expenditure requirement. Total approved project funding to date is C$15,091,000 of the $20,000,000 Earn-In requirement to reach 50% interest.

Rainer Ellmies, PhD, MScGeol, EurGeol, AusIMM and Vice President of Namibia Critical Metals Inc., is the Company's Qualified Person and has reviewed and approved this press release.

The common shares of Namibia Critical Metals Inc. trade on the TSX Venture Exchange under the symbol "NMI" and the OTCQB Market under the symbol "NMREF".

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For more information please contact -

Namibia Critical Metals Inc.

Darrin Campbell, President

Tel: +01 (902) 835-8760

Email: Info@NamibiaCMI.com

Web site: www.NamibiaCriticalMetals.com

This news release contains certain "forward-looking information" within the meaning of applicable securities laws. Forward looking information is frequently characterized by words such as "plan", "expect", "project", "intend", "believe", "anticipate", "estimate", "may", "will", "would", "potential", "proposed" and other similar words, or statements that certain events or conditions "may" or "will" occur. These statements are only predictions. Forward-looking information is based on the opinions and estimates of management at the date the information is provided, and is subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. For a description of the risks and uncertainties facing the Company and its business and affairs, readers should refer to the Company's Management's Discussion and Analysis. The Company undertakes no obligation to update forward-looking information if circumstances or management's estimates or opinions should change, unless required by law. The reader is cautioned not to place undue reliance on forward-looking information.

SOURCE: Namibia Critical Metals Inc.

View the original press release on ACCESS Newswire